In our recent virtual workshop, “From Spend-Based to Supplier-Specific Emissions Data,” we discussed different ways to calculate supply chain emissions and shared best practices for selecting the calculation method that is best for your organization.

You can watch a recording of the virtual workshop here. We’ve also summarized some key points from the workshop below.

Methods for calculating supply chain emissions

Scope 3, category 1 emissions, or emissions from upstream suppliers, tend to be the most significant portion of emissions for many companies. They are also notorious for being difficult to collect and calculate – and often require participation from outside of your organization.

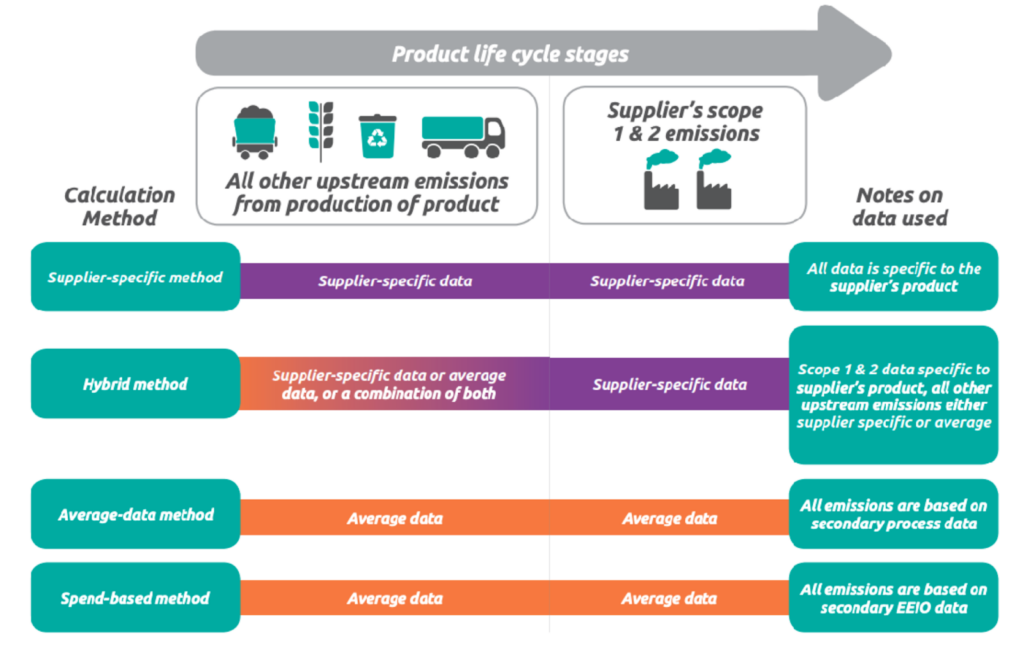

Not all methodologies require primary data from suppliers. Depending on your goals and access to primary data, there are multiple ways to calculate your supply chain emissions:

- Spend-Based Method: This method relies on expenditure data, providing a basic overview of procurement-related emissions. It serves as a starting point for many businesses.

- Average-Data Method: This method involves using industry-average emissions factors and activity data to estimate emissions created by your supply chain, without detailed data from specific suppliers or processes.

- Hybrid Method: This approach combines average data from Life Cycle Assessments (LCAs) with some supplier-specific information, striking a balance between accuracy and feasibility.

- Supplier-Specific Method: This is the most granular method, and involves obtaining emissions data directly from suppliers. While this is arguably the most difficult method of the four, it provides the most precise and actionable insights to inform your decarbonization efforts.

Most companies begin their supply chain emissions journey by utilizing the spend-based method and move towards hybrid and supplier-specific methods as they mature.

Determining which method to use

Although emissions data maturity is a good indicator of which method to use, selecting the appropriate calculation method hinges on various factors, which can include:

- Business goals and strategies: Is your organization currently setting science-based targets, related to scope 3, category 1? You should consider using supplier-specific data.

- Access to primary data: Do you lack primary emissions data from suppliers? If so, using a spend-based or average-data method may be the best starting place for you.

- Significance of scope 3, category 1 emissions: Are supply chain emissions a substantial part of your overall footprint? If so, calculating supplier-specific data will help you understand where to best make reductions.

Here’s an example of when a hybrid model might be appropriate:

Here’s an example of when a spend-based strategy might be appropriate:

No matter which method you use, make sure that your calculations are GHG Protocol-aligned. This way, your company will be able to comply with current and future regulations like California’s climate regulations and the SEC’s proposed climate disclosure rule.

How to start with supplier-specific data

If you’ve determined that your organization should be using supplier-specific data for your emissions calculations, this on-demand virtual workshop will walk you through best practices for collecting that data. In addition, the workshop hosts walk you through a free template for allocating those emissions to your own organization, depending on how much primary data you have.

If you’re interested in learning how Optera can help you transition from spend-based emissions to supplier-specific emissions, contact our team.